# Bag House Filter Calculation Tools and Units Available from China Factories

Table of Contents

Understanding Bag House Filter Calculation Tools

Bag house filters are essential components in various industrial applications, ensuring that air quality meets regulatory standards. The calculation tools designed for bag house filters help engineers and technicians determine the appropriate size and specifications of filters needed for specific applications. These tools can greatly streamline the design process, saving time and resources.

When selecting a calculation tool, it is crucial to consider the accuracy and reliability of the data provided. Many tools available in the market today, especially those sourced from reputable Chinese factories, are equipped with advanced algorithms that take into account various parameters such as airflow rates, dust load, and filter media characteristics. This ensures optimal performance and longevity of the bag house systems.

Utilizing these calculation tools can significantly improve operational efficiency. By accurately sizing the filters, businesses can reduce energy consumption and maintenance costs while maximizing filtration efficiency. This not only contributes to better air quality but also enhances the overall productivity of the manufacturing process.

Units of Measurement in Bag House Filters

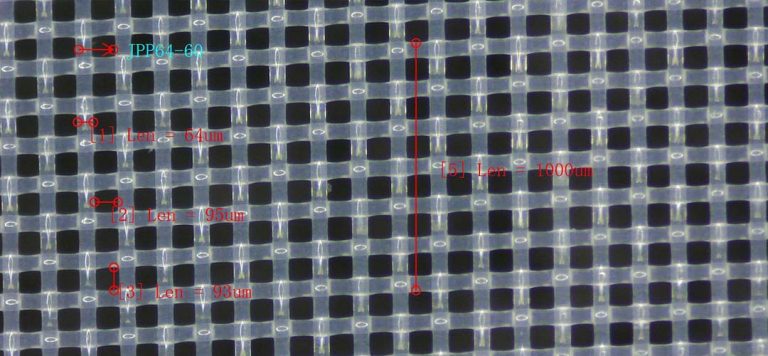

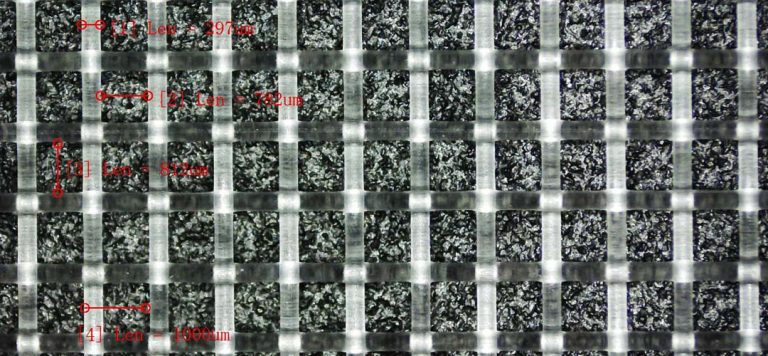

In the realm of bag house filters, understanding the units of measurement is vital for accurate calculations. Common units include cubic feet per minute (CFM) for airflow, square feet for filter area, and microns for particle size. Familiarity with these units allows users to effectively communicate technical specifications and requirements.

Chinese factories often provide detailed documentation on the units used in their products. This documentation is invaluable for engineers and buyers alike, as it ensures that everyone is on the same page regarding performance expectations. Additionally, many manufacturers offer conversion tools to facilitate the transition between different measurement systems, making it easier for international customers to work with their products.

Having a solid grasp of these units not only aids in the initial selection of bag house filters but also plays a critical role in ongoing maintenance and evaluation. Regular monitoring of filter performance metrics, expressed in these standardized units, can help identify potential issues before they escalate, ensuring long-term operational success.

Advantages of Sourcing from China Factories

Sourcing bag house filter calculation tools and units from Chinese factories comes with numerous advantages. One of the most significant benefits is cost-effectiveness. Chinese manufacturers often have lower production costs due to economies of scale and efficient labor practices, allowing them to offer competitive pricing without compromising quality.

Additionally, many Chinese factories are at the forefront of technological advancements, producing high-quality filtration solutions that meet international standards. This innovation ensures that the tools and units available for purchase are not only reliable but also incorporate the latest developments in filtration technology. As a result, businesses can feel confident in the performance of their bag house systems.

Moreover, the vast manufacturing capabilities in China mean that customers can find a wide range of products tailored to their specific needs. Whether it’s custom sizes, unique configurations, or specialized filter materials, Chinese manufacturers are often willing to collaborate to create solutions that fit exact requirements. This flexibility is a key advantage for companies looking to optimize their filtration processes.

Quality Assurance and Compliance Standards

When purchasing bag house filtration equipment from China, it is essential to consider quality assurance and compliance with international standards. Many reputable factories adhere to stringent quality control measures, ensuring that their products meet or exceed industry benchmarks. Certifications such as ISO 9001 are commonly sought after, providing assurance that the manufacturing processes are held to high-quality standards.

In addition to quality certifications, compliance with environmental regulations is another critical factor. Many Chinese manufacturers are increasingly focused on sustainable practices and eco-friendly materials. This commitment not only helps protect the environment, but it also aligns with the values of many modern businesses that prioritize sustainability.

It is advisable for buyers to conduct thorough research and request documentation related to quality assurance and compliance. Engaging with suppliers who can demonstrate their commitment to high standards will ultimately lead to better product performance and customer satisfaction in the long run.

Conclusion

By leveraging advanced bag house filter calculation tools and sourcing high-quality units from Chinese factories, businesses can enhance their filtration systems’ efficiency and effectiveness. Understanding measurement units, prioritizing quality assurance, and recognizing the advantages of sourcing from China can lead to significant operational improvements and cost savings. Investing in these resources is an essential step towards achieving optimal air quality in industrial settings.