# Discover the Benefits of Bag Filters for Your Industrial Needs

Table of Contents

What Are Bag Filters?

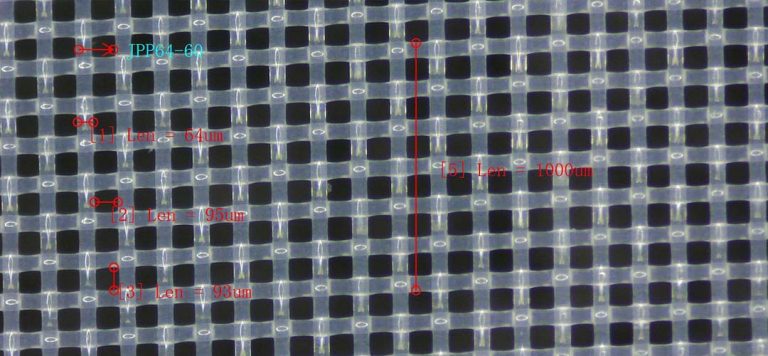

Bag filters are essential components used in various industries for filtering liquids and gases. They consist of a fabric material that captures particles, ensuring that only clean fluids pass through. This filtration method is highly effective for removing contaminants from industrial processes, making it a staple in sectors such as food and beverage, pharmaceuticals, and wastewater management.

The choice of a bag filter depends on the specific application and the type of particles that need to be filtered. Different materials and mesh sizes can be selected to meet unique requirements, offering versatility and efficiency in filtration solutions. By investing in high-quality bag filters, businesses can enhance their operational efficiency and product quality.

Advantages of Using Bag Filters

One of the primary advantages of bag filters is their cost-effectiveness. Compared to other filtration methods, bag filters often require lower initial investment and maintenance costs. Their design allows for quick replacement and minimal downtime, which means your production processes can continue smoothly without significant interruptions.

Additionally, bag filters provide a high level of filtration accuracy. They can effectively capture a wide range of particle sizes, ensuring that the final product meets industry standards. This reliability not only enhances product quality but also helps prevent equipment damage caused by contaminants, ultimately saving businesses money in repairs and replacements.

Selecting the Right Bag Filter for Your Application

When choosing a bag filter, it’s crucial to consider factors such as flow rate, temperature, and the chemical compatibility of the filter media. Each application has its own unique demands, and selecting the right filter will ensure optimal performance. An experienced supplier can help guide you through the selection process, ensuring that you choose a filter that fits your specific needs.

Moreover, understanding the specifications of your operation will help you determine the appropriate size and configuration of the bag filter. Whether you need a standard or customized solution, having the right information at hand will facilitate an informed decision, leading to better filtration results and improved overall efficiency.

Maintenance Tips for Bag Filters

Proper maintenance of bag filters is essential to maximize their lifespan and performance. Regular inspection is necessary to identify signs of wear or damage, allowing for timely replacement before issues arise. It’s also important to monitor the pressure drop across the filter, as an increase can indicate that the filter is becoming clogged and requires cleaning or replacement.

Cleaning methods can vary depending on the type of bag filter used. Some filters can be cleaned and reused, while others are designed for single-use. Establishing a routine maintenance schedule will help keep your filtration system running smoothly, ensuring that you maintain high-quality output and avoid unnecessary downtime.

The Future of Bag Filter Technology

As industries evolve, so does the technology behind bag filters. Innovations are continuously being made to improve the efficiency and effectiveness of filtration systems. Advancements such as nanofiber technology enhance the capability of bag filters to capture smaller particles, pushing the boundaries of what is possible in filtration.

Additionally, the integration of smart technology into filtration systems allows for real-time monitoring and data analysis. This not only improves maintenance practices but also helps companies optimize their processes based on actual performance data. Investing in modern bag filter technology can give businesses a competitive edge in today’s fast-paced market.